Products

Wall channel and stanchion heating systems

Thermatek® heating systems stop cold transfer preventing condensation and freezing on walls and stanchions, ensuring stability and efficiency.

The product

Product information

The edges, corners, and columns within cold stores and freezers are critical areas where condensation can form, potentially leading to ice accumulation or structural damage to adjacent rooms or spaces below.

Thermatek offers reliable, ultra-low voltage heating solutions designed to prevent ice and condensation, ensuring the integrity and safety of cold storage facilities.

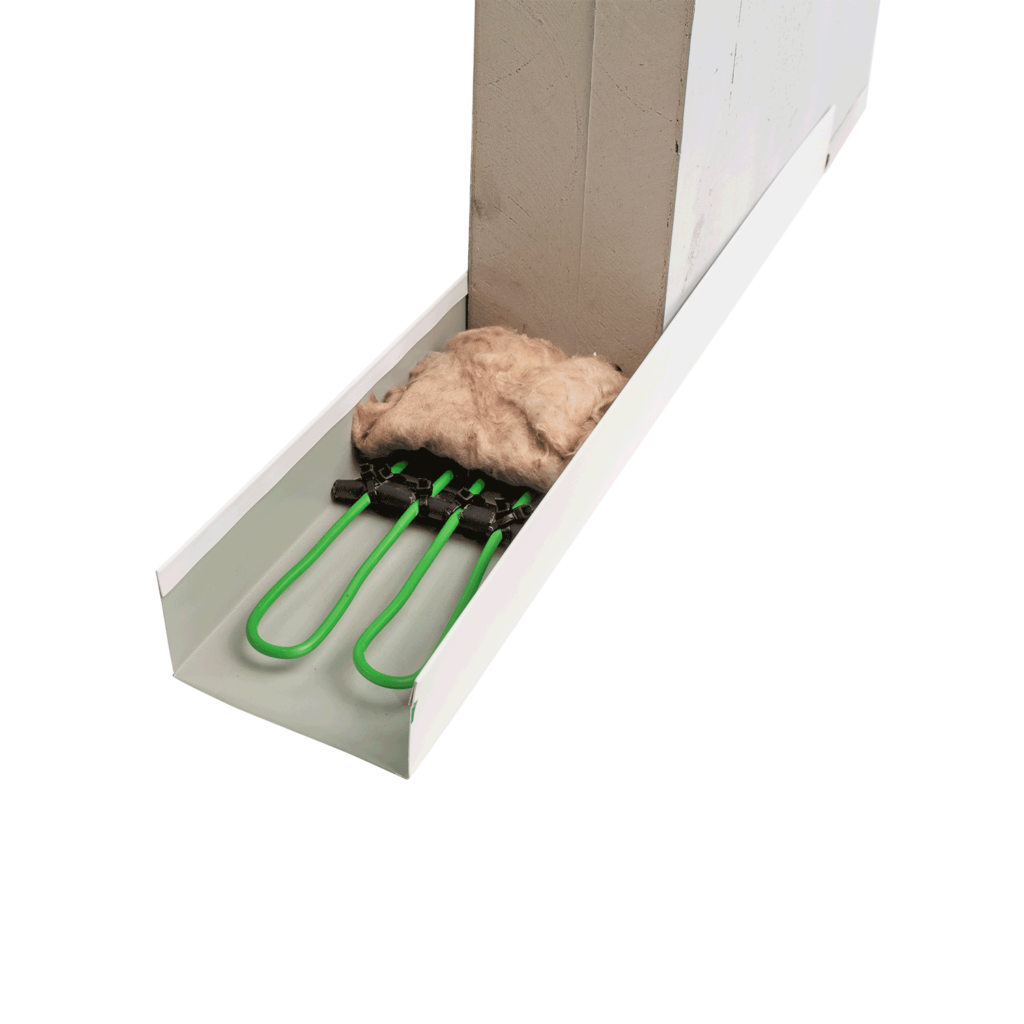

Wall Channel heating

Thermatek® low- and ultra-low voltage wall channel heating systems are installed during freezer construction to provide targeted heating at the base of walls. Durable heavy-gauge stainless steel heating elements are placed within channels, beneath the walls, to deliver sufficient heat, keeping the lower wall sections and freezer edges frost-free while consuming minimal energy.

Each system is powered by a custom-designed Thermatek® transformer, optimized to meet the specific heating requirements of the installation. This tailored approach ensures maximum energy efficiency and consistent performance.

Stanchion heating

Thermatek® stanchion heating systems prevent freezing along steel and concrete stanchions within cold rooms. Heating wires are strategically installed around or within the web of the stanchion, typically extending up to a height of 1 meter. This creates a thermal barrier that seamlessly connects with the frost heave prevention mat on the floor.

By preventing freezing temperatures from traveling down the column into the subfloor, Thermatek® stanchion heating protects structural integrity and ensures optimal performance in cold storage environments.

Discuss your project

Learn more about integrating Thermatek heating solutions.

Product tech sheets

Explore specifications, installation guidelines, and performance insights.

Wall channel & stanchion

sales@thermatek.co.uk

+44 1488 684888

Resources

Your questions about wall channel & stanchion systems.

Learn about Thermatek’s frost heave prevention technology, how our systems operate, and what sets them apart in the industry.

If using an ‘I’ or ‘H’ column, heating wires are supplied to be clipped or pinned to fit the web of the steel. If the column is of rectangular structure of concrete or steel, we design what we call a wrap-around heater wire which is fitted horizontally and clipped or pinned to the structure.

Stanchions or columns can run continuously directly from the transformer or can be thermostatically controlled with our standard or upgraded Tecnologic device range.

This will depend on the layout drawing we supply but basically centralised within the channel.

Not the wall channels, as this would require removing the walls, but we can design a stainless steel wire system running on the outside of the wall channel and on the floor directly connect to the channel to solve any problems.

Our references

Discover how Thermatek approach client’s challenge with bespoke solution to prevent their storage from frost heave.

Retail & food distribution

Our systems help major supermarket chains and food logistics providers prevent frost buildup, ensuring perishable goods remain safe and facilities operate efficiently.

Installation & maintenance

At Thermatek®, we don’t just supply heating systems — we ensure they perform flawlessly throughout their lifespan, providing design, consultancy, and technical support with over 35 year of expertise

Get in touch with us

Have a question about our heating solutions or need expert advice for your cold storage project? Our team is here to help. Contact us today to discuss your needs, request a quote, or get technical assistance.

Contact us today to discuss your needs, request a quote, or get technical assistance.

5a, Station Yard, Station Road, Hungerford RG17 0DY / UK

sales@thermatek.co.uk

+44 (0)1488 684888